Liquid packing equipment plays a crucial purpose inside the effective and accurate packaging in the significant sum liquid merchandise. Applied throughout industries like food and beverage, prescribed drugs, cosmetics, and chemicals, this machinery means that items is crammed, sealed, and packed quickly, hygienically, sufficient reason behind minimal waste. As prerequisite for precision and pace boosts, modern liquid packing equipment is now extra advanced, presenting Increased automation, flexibility, and dependability.

At its Main, liquid packing products encompasses quite a few integrated methods that really get the job done with each other to fill, seal, and get ready liquid solutions for distribution. These programs could include liquid fillers, capping devices, labelers, and carton sealers. The leading objective is usually to shift liquid from a storage tank or reservoir into containers like bottles, pouches, drums, or Bag-in-Box (BIB) formats with accuracy and performance.

Different forms of filling mechanisms are widely-utilised with regards on the viscosity while in the liquid in addition to the method of container. Gravity fillers and overflow fillers are very best for slender, absolutely free-flowing liquids like water or juice, while piston and pump fillers are improved suited to thicker, additional viscous substances for example sauces, oils, creams, and gels. Some equipment takes advantage of flowmeters or weigh scales to create certain exact dosing, that is crucial in industries in which products regularity is critical.

Modern liquid packing equipment usually incorporates consumer-helpful digital controls and touchscreens that let operators to change options conveniently and observe effectiveness in actual time. Clean up-In-Put (CIP) systems and stainless design manage hygiene requirements, particularly important in food and pharmaceutical purposes.

Just one standout Remedy with this particular area emerges by the likes of Flex Pack Service & Provides in Australia. They design and manufacture versatile, semi-computerized and guide liquid packing equipment tailor-made to precise manufacturing demands. Their devices can fill volumes from 0.5 to 1,000 get more info liters and manage a number of packaging formats, from bottles and casks to substantial industrial containers.

Some great benefits of employing liquid packing equipment are lots of: increased production pace, lowered labor charges, minimized item wastage, and improved packaging consistency. For firms looking to make improvements to operational performance and product excellent, committing to high-excellent liquid packing products are an smart and vital shift.

In conclusion, liquid packing equipment is a cornerstone of modern day manufacturing, providing the precision and gratifaction necessary to meet nowadays’s competitive sector requires.

Emilio Estevez Then & Now!

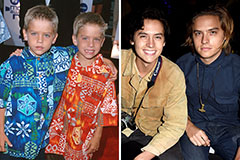

Emilio Estevez Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now!